Lean Project Management: The Complete Guide For A Successful Implementation

Introduction

Lean project management is an approach to managing projects that focuses on eliminating waste, streamlining processes, and maximizing efficiency. It is a structured way of working with teams to create the most value for customers in the shortest amount of time possible. With Lean project management, you can break down complex tasks into smaller steps that are easier to manage and complete.

By using lean principles, you will be able to deliver high-quality products faster than ever before while reducing costs and improving customer satisfaction. This comprehensive guide will provide an overview of what Lean Project Management is, how it works, and its benefits so you can get started right away!

With the adaption of lean project management process into the world of software development , it has become increasingly important to understand the fundamentals of this methodology.

Principles of Lean Project Management Methodology

In the lean production (which lead to lean project management), there are a few key principles that need to be followed by the project team in order to ensure the success of their project.

1. Eliminate Waste

One of the key principles of Lean Project Management is identifying and eliminating sources of waste. Waste can take many forms, both physical and non-physical, and can have a significant impact on the efficiency and effectiveness of a project. By eliminating waste, teams can focus on delivering maximum value to the customer while minimizing unnecessary activities or resources.

Physical waste refers to any unnecessary materials, resources, or equipment that is not needed to complete the project. This could include excess inventory, unnecessary tools, or even unused office space. Identifying and eliminating physical waste can help to reduce costs and increase efficiency. For example, if a team finds that they are consistently over-ordering a certain type of material, they can take steps to reduce their inventory levels and avoid overspending on unnecessary resources.

Non-physical waste refers to any unnecessary activities or processes that do not add value to the project. This could include lengthy meetings, excessive paperwork, or redundant tasks. Identifying and eliminating non-physical waste can help to improve communication and collaboration within the team, as well as increase overall productivity. For example, if a team finds that they spend hours each week in meetings that do not add value to the project, they can take steps to reduce the number of meetings or make them more efficient.

2. Focus on the Customer

One of the key principles of Lean Project Management is to focus on delivering value to the customer. This means that teams should prioritize the work that will have the greatest impact on the customer and eliminate activities or processes that do not add value. By focusing on delivering value, teams can ensure that they are providing a product or service that is truly useful and valuable to the customer.

3. Continuous Improvement

Lean Project Management promotes an iterative approach to project management, which emphasizes continuous assessment and improvement of processes. By regularly reviewing and refining processes, teams can ensure that the project stays aligned with customer needs and adapts to changes in the environment. This helps to ensure that the project delivers maximum value to the customer and remains efficient and effective over time.

Iteration allows teams to make incremental improvements, rather than waiting until the end of the project to address issues. This approach allows teams to identify and correct problems early on, reducing the risk of delays and budget overruns. It also enables teams to incorporate feedback from customers and stakeholders, ensuring that the project stays aligned with their needs and expectations.

4. Embrace Collaboration

Lean Project Management emphasizes collaboration and communication between teams and stakeholders. By fostering an environment of collaboration, teams can make faster decisions, improve communication, and ultimately increase customer satisfaction.

Collaboration allows teams to share ideas and best practices, which can lead to more efficient and effective solutions. It also enables teams to work together to identify and resolve issues more quickly, which can reduce the risk of delays and budget overruns. Collaboration also helps to ensure that everyone is working towards the same goals and that the project stays aligned with customer needs.

Effective communication is also a key aspect of collaboration in Lean Project Management. By keeping all stakeholders informed and involved throughout the project, teams can ensure that everyone is on the same page and that the project stays aligned with customer needs. Regular check-ins, feedback loops, and active engagement with stakeholders are critical to effective communication, which can help to improve transparency, accountability, and trust.

5. Encourage Visibility

Lean Project Management encourages transparency and visibility throughout the project. This principle is important for ensuring that the project stays on track, that potential issues are identified early on, and that corrective action can be taken quickly to minimize their impact on the project.

Transparency in project management means that all stakeholders have access to accurate and up-to-date information about the project’s progress. This includes project timelines, budgets, and key performance indicators (KPIs). By providing transparent information, teams can ensure that everyone is aware of the project’s status, which can help to identify potential issues early on and take corrective action.

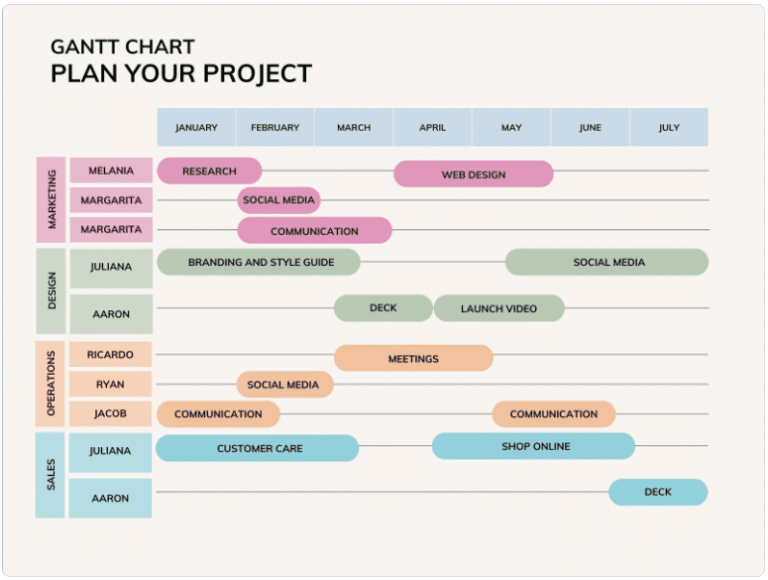

Visibility in project management refers to the ability to easily see the progress of the project, including the work that has been completed, the work that is currently underway, and the work that remains to be done. This can be achieved through the use of project management tools, such as Gantt charts, Kanban boards, and burndown charts. By providing visibility into the project’s progress, teams can ensure that everyone is aware of the project’s status and can take corrective action as needed.

The Lean Project Management Framework

Lean methodology in practice involves a set of tools, techniques, and principles that enable teams to work more efficiently and ensure successful project delivery. At the core of this lean management approach is the Lean Project Management framework designed to help teams eliminate waste and optimize the value of their projects.

Define

In the Define phase, the project team identifies the problem or opportunity that the project is intended to address. It is important to clearly define the problem or opportunity in order to ensure that the project stays on track and meets its goals.

Measure

During the Measure phase, the team collects data and establishes a baseline for the project. This data is used to create a benchmark for future improvements and to identify areas for improvement.

Analyze

The Analyze phase is where the team uses the data collected in the Measure phase to identify the root cause of the problem or opportunity. This phase is critical in understanding the underlying issues and identifying potential solutions.

Improve

In the Improve phase, the team implements solutions to address the issues identified in the Analyze phase. This phase is focused on delivering maximum value while minimizing waste.

Control

The Control phase is where the team monitors and maintains the improvements made in the Improve phase. This phase is essential in ensuring that the project stays on track and that the improvements are sustained over time.

Lean Project Management Tools and Techniques

Lean Project Management emphasizes the use of tools and techniques to improve the project process and optimize the project lifecycle. One of the key tools used in Lean Project Management is project management software, which helps teams to streamline their project process, increase visibility and transparency, and stay on track throughout the project lifecycle. In this section, we will explore some of the most popular Lean Project Management tools and how they can be used to improve the project process and optimize the project lifecycle.

Kanban

Kanban is a visual tool used to manage and track the progress of work items. It is a powerful tool that can be used to increase transparency and communication within a project team.

Scrum

Scrum is a framework that can be used to manage and deliver complex projects. It is an iterative and incremental approach that prioritizes flexibility and adaptability. Learn more about Scrum Masters here.

Value Stream Mapping

Value Stream Mapping is a tool used to identify and eliminate waste in a process. It is a powerful tool that can be used to increase efficiency and reduce costs.

5S

5S is a method used to create a clean, organized and efficient workspace. It is a powerful tool that can be used to improve productivity and safety in the workplace.

Six Sigma

Six Sigma is a methodology that focuses on quality and process improvement. It is a powerful tool that can be used to reduce defects and increase customer satisfaction.

Implementing Lean Project Management

Lean project management focuses on improving efficiency and eliminating waste in the project lifecycle. To do this, teams should consider implementing some of the following techniques:

Identifying the project team

The first step in implementing Lean Project Management is to identify the project team. This should include people with a range of skills and experience, as well as stakeholders who can provide valuable insight into the project.

Setting project goals and objectives

The project team should then define the project goals and objectives. This will ensure that everyone has a clear understanding of what needs to be achieved.

Creating a project plan

The project plan should include milestones, tasks and deliverables. This will provide the team with a roadmap for completing the project on time and on budget.

Monitoring and reviewing progress

The project team should monitor and review progress throughout the project. This will allow them to identify issues quickly, take corrective action and ensure that the project is on track.

Making adjustments

Implementing Lean tools and techniques

The project team should also implement Lean tools and techniques to help streamline their workflow. This could include Kanban, Scrum, Value Stream Mapping and 5S.

Measuring progress and success

The project team should also measure progress and success throughout the project. This could include tracking key performance indicators, conducting customer surveys or assessing overall satisfaction levels.

Challenges and Best Practices

Implementing Lean Project Management can present its own set of challenges, especially for lean project managers who are responsible for aligning their project’s execution with the lean philosophy and customer requirements. A well-crafted project management plan that incorporates Lean principles is essential to overcome these challenges and deliver successful projects.

In this section, we will discuss some of the common challenges faced in Lean Project Management and the best practices that can be implemented to overcome them, such as aligning the project plan with the customer requirements, and incorporating lean philosophy in the project management plan.

Common challenges in implementing Lean Project Management

1. Resistance to change

One of the common challenges in implementing Lean Project Management is resistance to change. Employees may be hesitant to adopt new processes or tools, and may be resistant to making changes to their existing ways of working. This can make it difficult to implement Lean principles and practices, and can slow down the progress of the project.

2. Lack of understanding

Another common challenge is a lack of understanding of the principles and practices of Lean Project Management. Without a clear understanding of how Lean works, it can be difficult to implement the methodology effectively. This may lead to misunderstandings, confusion, and inefficiency, which can slow down the progress of the project.

3. Limited resources

Implementing Lean Project Management can be resource-intensive, and teams may struggle with limited resources. This can make it difficult to implement Lean tools and techniques, and can limit the scope and scale of the project. Limited resources can also impact the team’s ability to track progress and measure success, which can make it difficult to identify areas for improvement.

Best practices for overcoming these challenges

1. Communicate the benefits

One of the best ways to overcome resistance to change is to communicate the benefits of Lean Project Management. By clearly explaining how Lean can improve processes, increase efficiency, and deliver value to the customer, teams can help to build buy-in and support for the methodology.

2. Provide training and education

To overcome a lack of understanding, it is important to provide training and education on the principles and practices of Lean Project Management. By providing a clear and thorough understanding of the methodology, teams can better equip themselves to implement Lean effectively.

3. Prioritize and focus

When facing limited resources, it is important to prioritize and focus on the most important aspects of the project. By focusing on the most critical elements of the project, teams can ensure that they are making the most of their resources and delivering maximum value to the customer.

Strategies for maintaining a Lean project management approach

1. Regularly review and improve processes

One of the key strategies for maintaining a Lean project management approach is to regularly review and improve processes. This includes continuously monitoring progress, identifying areas for improvement, and making incremental changes to processes. By staying vigilant and proactive in the process of improvement, teams can ensure that the project remains aligned with customer needs and adapts to changes in the environment.

2. Encourage employee participation

Another important strategy is to encourage employee participation in the Lean project management process. By giving employees the opportunity to provide feedback and suggestions, teams can ensure that everyone is invested in the success of the project. Furthermore, by involving employees in the process of improvement, teams can tap into the collective knowledge and expertise of the team, which can lead to more effective solutions.

3. Measure and track progress

Measuring and tracking progress is crucial for maintaining a Lean project management approach. By regularly monitoring key performance indicators (KPIs) and using data to inform decisions, teams can ensure that the project stays on track and that the improvements are sustained over time. This allows teams to make adjustments as needed and to identify new areas for improvement.

Lean Project Management Certifications

Obtaining a certification in Lean Project Management can demonstrate a level of expertise and commitment to the methodology for project managers. The Project Management Institute (PMI) offers certifications that validate a project manager’s understanding and application of lean thinking in their work. In this section, we will explore the various certifications offered by PMI and how they can help project managers to demonstrate their proficiency in Lean Project Management and advance their career.

Obtaining a certification in Lean Project Management can demonstrate a level of expertise and commitment to the methodology. There are several certifications available, each with their own set of pros and cons. In this section, we will explore some of the most popular certifications and their respective benefits and drawbacks.

Lean Six Sigma Green Belt

The Lean Six Sigma Green Belt certification is a widely recognized certification that demonstrates a solid understanding of the Six Sigma methodology and its application in Lean Project Management. Pros of this certification include its emphasis on process improvement and its wide recognition in the industry. Cons include the cost and time commitment required to obtain the certification.

Scrum Alliance Certified ScrumMaster (CSM)

The Scrum Alliance Certified ScrumMaster (CSM) certification demonstrates a solid understanding of the Scrum framework and its application in Lean Project Management. Pros of this certification include its emphasis on adaptability and its wide recognition in the industry. Cons include the cost and time commitment required to obtain the certification, and it’s limited to Scrum framework only.

Association for Talent Development (ATD) Lean Six Sigma Yellow Belt

The Association for Talent Development (ATD) Lean Six Sigma Yellow Belt certification is a widely recognized certification that demonstrates a basic understanding of the Six Sigma methodology and its application in Lean Project Management. Pros of this certification include its emphasis on process improvement and its wide recognition in the industry. Cons include the cost and time commitment required to obtain the certification.

Obtaining a certification in Lean Project Management can demonstrate a level of expertise and commitment to the methodology. However, it’s important to research the certifications available and evaluate the pros and cons of each to determine which one aligns best with your learning objectives and career goals.

Conclusion

Hopefully this post answered all of your questions regarding Lean Project Management, its strategies and certifications. Ultimately, while certification can demonstrate a commitment to the methodology and provide an edge in the job market, the best way to ensure successful Lean Project Management is to adopt a continuous learning and improvement mindset. By utilizing the strategies outlined in

Bonus: History of Lean Project Management

Lean Project Management has its roots in the principles of Lean manufacturing, which originated from the Toyota Production System (TPS). The TPS was developed by Taiichi Ohno at Toyota in the 1930s, with the goal of creating a more efficient and effective manufacturing process. The principles of TPS were later adapted for use in the project management field and became known as Lean Project Management.

Contrary to the popular perception, Agility was used in manufacturing processes before the Software industry adopted it wholesale.

You might also want to check out career guides for Product Owner, RTE, IT career switch. More from author here